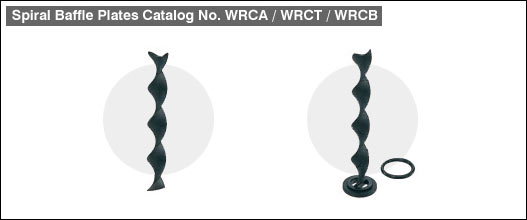

#002 Introduction to Products by Misumi ~ Spiral Baffle Plates

In the molds used for plastic injection molding from now on, molding in a stable manner maintaining the shape of the molded item accurately is considered as the minimum specification, and in addition, the evaluation of the mold will vary depending on how short the molding cycle can be made.

Normally, the cooling process is the most important among the processes of the molding cycle. In order to shorten the time of the cooling process, it is very important to remove the heat efficiently from the cavity surface after the filling of the molten plastic is completed and to quickly reduce the surface temperature of the molded item.

Although flow paths are provided in a mold for passing cooling water (or cooling oil), it is not necessarily possible that effective cooling is obtained using only simple cooling holes. In order to make the coolant (liquid) act effectively, a very effective means is to take some measures to make the time and area over which the coolant comes into contact with the heat generating part larger. A very common measure is a baffle plate. The leading part of the coolant that hits against the baffle plate flows inside the cooling hole along the baffle plate and removes the heat.

This principle is utilized in the "Spiral baffle plates" of the WRCA, WRCT, and WRCB series. A spiral baffle plate increases the probability of the coolant contacting the inside surface of the cooling holes because the coolant (liquid) flows inside the cooling hole while rotating through a spiral flow path, and hence it is possible to cool the mold more effectively. In addition, one of the features of this product is that it can be easily assembled and adjusted. Since it is made of nylon plastic (with 30% glass fibers), it can be easily cut to the necessary length at the assembling site to match the depth of the cooling water hole. In addition, it is possible to easily remove the baffle plates when dismantling the mold, and even removing the water stains can be easily done.

Since it is quite difficult to shorten the cooling cycle with only one definitive means, it is better to carry out improvements steadily while adding several small measures one by one. As one such measure, please try using the spiral baffle plates.