#292 Plating on Ceramics

Industrial materials used as non-conducting substances include plastics, rubbers, and ceramics. This lesson introduces plating on ceramics.

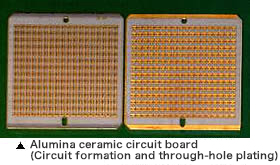

Ceramics are used for electrical components and semiconductor parts for its superior electrical insulation, high frequency characteristics, heat resistance, thermal conductivity and more. However, to use ceramics in electrical applications, a part of the ceramics must be metalized in order to allow formation of necessary electrodes and circuits.

Ceramics can be metalized by various methods from metal deposition and sputtering to a baking process using silver paste. Considering the reliability in terms of adhesion and precision, it is best to adopt the electroplating method.

The common procedure is as follows:

Degreasing → Surface Conditioning → Etching → Catalyzing →

Electroless Plating → Electroplating

As you can see, the ceramic plating process is basically same as the plastic plating process. The difference here is the type of solution used. [Table] lists the purposes and applications of plating used for electrical components.

[Table] Purposes and applications of plating on ceramics

|

- Environmental conservation

- Hot Dipping

- Anodic Oxidation Process

- Anodic oxidation treatment

- Anodizing

- Corrosion - Corrosion Protection

- Electroless Plating

- Electroplating

- Heat treating

- Hydrogen embrittlement

- Metal cleaning

- Metal etching

- Painting

- Special paints

- Surface Treatment

- Surface-treated steel sheets

- Thermal Spraying