#334 Applications of Thermal Spraying

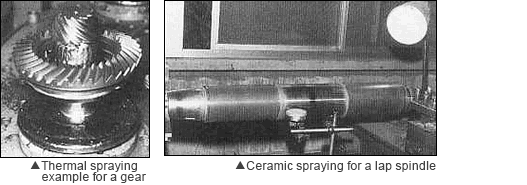

The surface reforming of material by thermal spraying is applied in various fields in order to improve functionalities, including abrasion, heat, oxidation and corrosion resistance, as well as enhancing electrical conductivity, insulation, dimensional restoration, clearance control, and so on.

Conventionally, the most common thermal spraying methods were the zinc and aluminum spraying which is designed to add rustproof properties to steel structures, and the build-up spraying applied for restoring the worn areas of mechanical components. In recent years, thermal spraying methods are adopted more frequently for improving functionalities during the designing phase.

Taking advantage of the characteristics of spray films, thermal spraying is also popular in the high-tech developments, such as when adjusting the surface roughness or forming porous solid electrolytes.

[Table] Applications of thermal spraying

|

- Environmental conservation

- Hot Dipping

- Anodic Oxidation Process

- Anodic oxidation treatment

- Anodizing

- Corrosion - Corrosion Protection

- Electroless Plating

- Electroplating

- Heat treating

- Hydrogen embrittlement

- Metal cleaning

- Metal etching

- Painting

- Special paints

- Surface Treatment

- Surface-treated steel sheets

- Thermal Spraying