#301 Dispersal (Composite) Plating of Precision Parts

Dispersal plating, which is also called composite plating, involves dispersion of chemically insoluble fine particles such as ceramic particles in electroplating or electroless plating baths to co-precipitate them with the plating metal. Nickel plating bath is generally used as the plating bath.

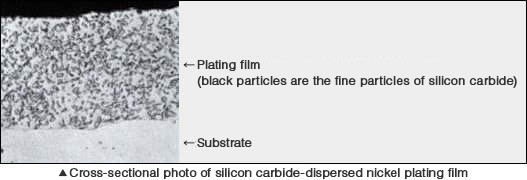

[Photo 1] shows a cross section of silicon carbide (SiC) -dispersed nickel plating film. It shows that silicon carbide is evenly dispersed in the nickel film and is also exposed on the film surface. The properties of the dispersed particles determine the characteristics of the plating film, such as enhanced wear resistance or self-lubricity.

[Table] shows the plating types and film characteristics of dispersal plating.

[Table] Plating types and film characteristics of dispersal plating

|

[Photo 1]

| Titanium carbide and tungsten carbide are co-precipitated in gold or palladium plating used for electrical contacts, or graphite is co-precipitated in palladium plating to improve wear resistance. |  |

| *Self-lubricity means that the film itself has lubricity and is capable of preventing wear without use of a lubricant. It is an essential property for devices used in space and vacuum. Non adherence means that an object does not stick to or repels other objects and contributes to dust-proofing, easy sliding, wear resistance, and contamination resistance. |

- Environmental conservation

- Hot Dipping

- Anodic Oxidation Process

- Anodic oxidation treatment

- Anodizing

- Corrosion - Corrosion Protection

- Electroless Plating

- Electroplating

- Heat treating

- Hydrogen embrittlement

- Metal cleaning

- Metal etching

- Painting

- Special paints

- Surface Treatment

- Surface-treated steel sheets

- Thermal Spraying