#302 Electroforming of Precision Parts

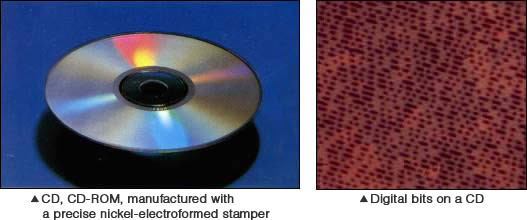

Electroforming is an applied technique of electroplating by which an article is coated with a very thick plating. One of its characteristics is the capability of faithfully reproducing the shape of a master block (transferability). It is used in many fields, including multi-media, such as CDs and CD-ROMs, electric razor blades, and various molds.

Characteristics and applications of industrial electroforming are summarized in the Table.

[Table] Characteristics and applications of industrial electroforming

|

Electroforming has the following characteristics: 1. excellent transferability; 2. high dimensional accuracy; 3. freely-changeable electrodeposition thickness; 4. unaffected by the shape and dimensions of the workpiece; and 5. capable of manufacturing hollow articles; etc.

As a reference for transferability, accuracy is said to be 0.05 to 0.2 um, depending on the precision of the master block and plating conditions. It is widely known that stampers (molds) for manufacturing CDs and CD-ROMs leverage this accuracy.

- Environmental conservation

- Hot Dipping

- Anodic Oxidation Process

- Anodic oxidation treatment

- Anodizing

- Corrosion - Corrosion Protection

- Electroless Plating

- Electroplating

- Heat treating

- Hydrogen embrittlement

- Metal cleaning

- Metal etching

- Painting

- Special paints

- Surface Treatment

- Surface-treated steel sheets

- Thermal Spraying