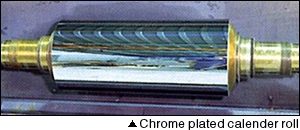

#135 Industrial Chrome Plating

The industrial chrome plating, also customarily called hard chrome plating, has been in wide usage in many areas in 10 ~ 100μm thickness due to its chrome coating hardness, lubrication retention ability, and wear resistant properties.

The industrial chrome plating coating properties are as follows.

(1) High hardness

Hardest among the standard electroplating (Macro Vickers hardness approx. 1000). Much harder than heat treated or nitrided steels.

(2) Wear resistance

The most importantly expected property for the chrome plating, and fully satisfies the reqirements.

(3) Corrosion resistance

Good corrosion resistance against chemicals other than chlorides, and is stable in the atmosphere.

(4) Heat resistance

When heated, hydrogen occluded in the coating is released and the hardness lowers. When exceeding 300°C, the hardness rapidly lowers. Therefore, the wear resistance is also decreased.

[Table] Examples of industrial chrome application areas and purposes

|

- Environmental conservation

- Hot Dipping

- Anodic Oxidation Process

- Anodic oxidation treatment

- Anodizing

- Corrosion - Corrosion Protection

- Electroless Plating

- Electroplating

- Heat treating

- Hydrogen embrittlement

- Metal cleaning

- Metal etching

- Painting

- Special paints

- Surface Treatment

- Surface-treated steel sheets

- Thermal Spraying