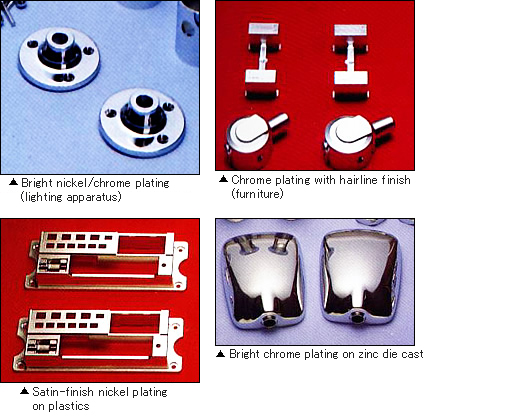

#255 Decorative Chrome Plating

The most common and long-established method of decorative plating on a steel substrate is copper-nickel-chrome plating or so called 'chrome plating'. In recent years, nickel-chrome plating (semi-bright + bright plating) is also common for its superior corrosion resistance and aesthetic properties. These are not only applied over metal substrates but also applied over plastic substrates. Chrome plating is the mainstream of decorative plating today.

Since chrome plating provides various surface properties including satin, hairline, spin, diamond cut, semi-bright satin, velour, pearl pattern finishes in addition to mirror gross finish, each type of finish is adopted for corresponding purposes.

Today's automobile industry requiring higher corrosion resistance is using dual plating consisting of electrochemically different nickels, triple plating with the medium layer made of trinickel, and microcracked chromium plating for the top layer to improve corrosion resistance.

The other types of decorative plating include nickel plating adopted for the top layer instead of chrome plating to produce reddish gross finish, and bright copper plating on the top for bronze finish.

- Environmental conservation

- Hot Dipping

- Anodic Oxidation Process

- Anodic oxidation treatment

- Anodizing

- Corrosion - Corrosion Protection

- Electroless Plating

- Electroplating

- Heat treating

- Hydrogen embrittlement

- Metal cleaning

- Metal etching

- Painting

- Special paints

- Surface Treatment

- Surface-treated steel sheets

- Thermal Spraying