#296 Silver Plating for Electronics

Similarly to industrial gold plating, industrial silver plating is also essential to electronics-related components. Among metals, silver, which is less expensive than gold, has the best electrical conductivity. It also has an excellent thermal conductivity, lubricity, and heat resistance, and therefore is used widely, not only in the electronics industry, but also in the electrical engineering and aircraft industries.

Applications and purposes of industrial silver plating are summarized in the Table.

[Table] Applications and purposes of industrial silver plating

|

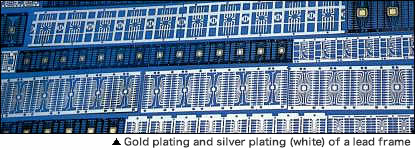

Silver plating, like gold plating, also uses both soft and hard silver. Soft silver plating is used as a substitute to gold plating for parts that require high electrical conductivity, such as lead frames and stems. Hard silver plating is used for parts with an emphasis on wear resistance, such as connectors, terminals, and switch contacts.

Silver plating is susceptible to sulphide staining caused by sulfur in the environment. Therefore, anti-tarnish treatment, such as chromating and oil coating, is carried out after silver plating.

- Environmental conservation

- Hot Dipping

- Anodic Oxidation Process

- Anodic oxidation treatment

- Anodizing

- Corrosion - Corrosion Protection

- Electroless Plating

- Electroplating

- Heat treating

- Hydrogen embrittlement

- Metal cleaning

- Metal etching

- Painting

- Special paints

- Surface Treatment

- Surface-treated steel sheets

- Thermal Spraying