HOME > Surface Finishing Tutorial > #299 Tin-Lead Alloy/Lead Plating for Electronics

Surface Finishing Tutorial

#299 Tin-Lead Alloy/Lead Plating for Electronics

Category : Electroplating

July 7, 2017

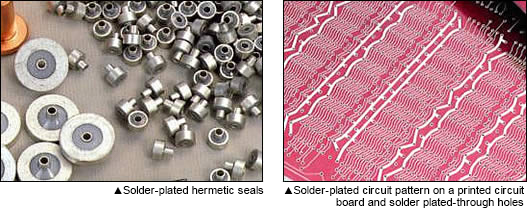

(1) Tin-lead alloy plating

|

Tin-lead alloy plating is widely used for electronics as solder plating.Solder plating has two types: molten soldering and electroplating. The former is used for printed circuit boards, whereas the latter is used for components that require dimensional accuracy and film uniformity and adhesion. The alloy composition is controlled by the bath composition and working conditions. The alloy ratios shown in the table are used according to the intended purposes, including corrosion resistance, flexibility, lubricity, and solderability. For mitigation of whisker growth on tin-plated electrical and/or electronic-related components, solder plating containing 5-10% lead is used. Although the purpose of plating is to prevent corrosion, alloy plating containing 5-7% tin is used, instead of pure lead plating.Lead-antimony alloy plating is used for parts that require wear resistance. |

[Table] Applications and alloy ratios of solder plating

|

(2) Lead plating

Although the purpose of lead plating is to prevent corrosion, alloy plating containing 5-7% tin is used, instead of pure lead plating. Lead-antimony alloy plating is used for parts that require wear resistance.

| * | Precautions for solder plating and lead plating Plating metals used for solder plating and lead plating diffuse into the basis metal. In order to prevent this, a copper or nickel base-coat plating is necessary. |

| * | As a measure for preventing environmental lead contamination caused by, for example, acid rain falling on discarded electronic equipment, a shift toward lead-free soldering and solder plating is accelerating. |

- Environmental conservation

- Hot Dipping

- Anodic Oxidation Process

- Anodic oxidation treatment

- Anodizing

- Corrosion - Corrosion Protection

- Electroless Plating

- Electroplating

- Heat treating

- Hydrogen embrittlement

- Metal cleaning

- Metal etching

- Painting

- Special paints

- Surface Treatment

- Surface-treated steel sheets

- Thermal Spraying