HOME > Surface Finishing Tutorial > #307 Print and Electroplating

Surface Finishing Tutorial

#307 Print and Electroplating

Category : Electroplating

September 1, 2017

|

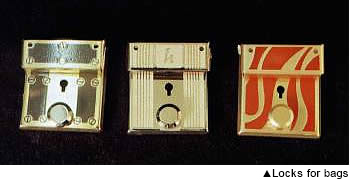

Printed wiring boards, which are the essential item for electrical devices and communication equipment, are the typical example of products made by printing and plating work combined.An original plate of a print wiring board is a plastic sheet totally covered with a copper foil. To form a desired electrical circuit using this copper foil, the screen with the circuit pattern laid out must be prepared so that the resist can be printed on this foil. Unnecessary copper foil needs to be removed by the etching process. To increase the electrical capacity, copper plating should also be applied on the circuit.If necessary, tin plating, solder plating, nickel plating, or gold plating can also be applied. One of the common conventional methods of adding decorative finish to the interior, personal ornaments and furniture is to print the engraved resist pattern from the metal surfaces through etching while protecting the substrate where needed. Nowadays, this conventional method combined with different forms of electroplating, such as dispersal plating, electroforming, and paint application is used to create contemporary and stylish products. |

|

- Environmental conservation

- Hot Dipping

- Anodic Oxidation Process

- Anodic oxidation treatment

- Anodizing

- Corrosion - Corrosion Protection

- Electroless Plating

- Electroplating

- Heat treating

- Hydrogen embrittlement

- Metal cleaning

- Metal etching

- Painting

- Special paints

- Surface Treatment

- Surface-treated steel sheets

- Thermal Spraying