#257 Oxidized Finish for Decoration

An oxidized finish, which gives copper or copper alloy products an aesthetic effect, is achieved by blackening the surfaces with sulfidization treatment and buffing off some of the coloring. This process adds an antique look produced by black contrast and color gradation mixed with reddish tone of plating.

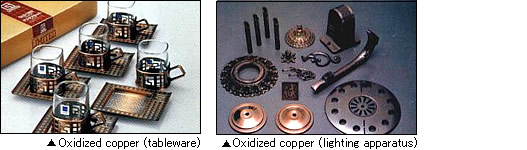

Including interior decor items, this technique is used for accessories, fine arts and crafts, and lighting apparatus. The following [Table] shows the methods of various oxidized finish techniques.

[Table] Types of oxidized finish

|

In any of the above cases, the common method is to plate the substrate with nickel or copper (bottom plating) to improve corrosion resistance before applying an oxidized finish.

Since the surfaces after applying an oxidized finish are extremely prone to abrasion, the routine process is to apply clear coating such as by electrostatic spray painting to protect the surfaces. For items requiring the high degree of abrasion resistance, tableware for example, the coating with the high pencil hardness will be adopted.

- Environmental conservation

- Hot Dipping

- Anodic Oxidation Process

- Anodic oxidation treatment

- Anodizing

- Corrosion - Corrosion Protection

- Electroless Plating

- Electroplating

- Heat treating

- Hydrogen embrittlement

- Metal cleaning

- Metal etching

- Painting

- Special paints

- Surface Treatment

- Surface-treated steel sheets

- Thermal Spraying