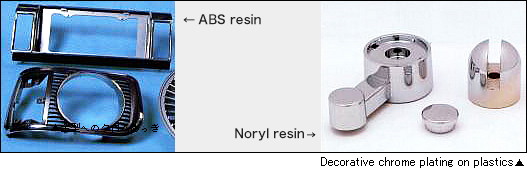

#258 Decorative Plating for Plastics

Various plastics have substituted metal materials in many fields for their advantages (including lightweight, mass productivity, and cost reduction, etc.).

Applying electroplating on plastic materials not only enhances the product value by adding metallic appearance but also improves resistance to weather, light, heat, shock, abrasion and bacteria when the metal coating over the entire plastic surface protects it from the external environment. The plating can also make them look more luxurious and give additional value to the plastic products.

Formerly, commodity plastics (long-term heat resistant temperature is less than 100℃), such as ABS (Acrylonitrile-Butadiene-Styrene) and PP (Polypropylene), were the most common item. However, in line with the technology advancement, various types of high-performance engineering plastics have been developed in recent years. Not all types of plastics can be plated. The table below shows plastics compatible with plating.

[Table] Plating-compatible plastics

|

- Environmental conservation

- Hot Dipping

- Anodic Oxidation Process

- Anodic oxidation treatment

- Anodizing

- Corrosion - Corrosion Protection

- Electroless Plating

- Electroplating

- Heat treating

- Hydrogen embrittlement

- Metal cleaning

- Metal etching

- Painting

- Special paints

- Surface Treatment

- Surface-treated steel sheets

- Thermal Spraying