#330 Know-how on automation: Pressurized heating technology - 2: Pressurization method and pressure profile

Pressurization method generally determines its pressure profile.The pressure profile, however, changes even with the same pressurization method depending on the (1) area of pressurization surface in comparison with the size of workpiece, (2) the property of elastic body of pressure buffer material, etc.This section describes the pressurization method and pressure profile.

(1)Pressurization method and pressure profile

1)Pressurization method - A

・Pressurization method - A is used in the case where pressure is applied to the area inside the circumference of the workpiece to pressurize the inner side of the workpiece using pressurization buffer material.

・The figure below illustrates the pressure profile in this case.The contact stress peaks at the circumference edge of the pressurization buffer material, and it begins to fall toward the center of the workpiece.

・Use of the pressurization buffer material will give some allowance for the parallel precision required for the opposing surfaces of the pressurization plate and the base plate, and rigidity of the whole mechanism.

2)Pressurization method - B

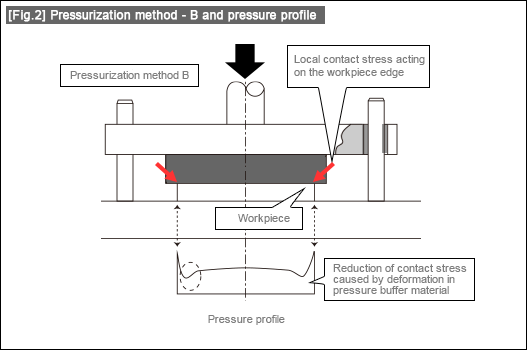

・Pressurization method - B is used in the case where pressure is applied to the whole area of the workpiece when the pressurization buffer material is larger than the workpiece (Fig. 2).

・In this case, the contact stress to pressure buffer material acts intensively upon the circumference edge area of the workpiece in the directions indicated by the red arrows.This intensive contact stress onto the edge area causes local deformation of the pressurization buffer material inside the edge area, which results in a sudden reduction of contact stress in the adjacent side of the circumference (Fig. 3).

・This reduction of contact stress in the adjacent side of the circumference will cause unevenness of bonding or uniformity in a fine gap between two panes of glass substrates, which affects product quality (Fig. 4).

・Selecting appropriate property of elasticity such as hardness of pressurization buffer material can restrain reduction of contact stress in the adjacent side of the circumference to a certain extent, but there are no fundamental countermeasures effective for the issue.

・In both pressurization methods A and B, distribution states of contact stress are more complex and the precision tends to deteriorates on the corners of the workpiece.

・The pressure buffer materials (rubber elastic body) also need replacement at a constant interval, etc. for management because there involve factors for variations in quality such as change in hardness or unrecoverable deformations caused by thermal effects from the heat treatment process or aging.

- Positioning technology

- Designing and processing

- Sensor Technology

- Automation elements technology

- Clean room technology

- Design hints

- Design tips

- Designing and Machining

- Drive mechanism design

- Hints on designing

- Linear Motion Components

- Locating Technology

- Manufacturing technology

- Motion mechanism design

- Pneumatic Drives

- Production Technology

- Technology Outlook

- General description

- Low-cost automation and materials

- Transfer LCA

- #333 Know-how on automation: Pressurized heating technology - 5: Multilayer pressurized heating process technique

- #332 Know-how on automation: Pressurized heating technology - 4: Points to remember when designing mechanism of pneumatic pressurization method

- #331 Know-how on automation: Pressurized heating technology - 3: Pneumatic pressurization method and pressure profile

- #330 Know-how on automation: Pressurized heating technology - 2: Pressurization method and pressure profile

- #329 Know-how on automation: Pressurized heating technology