HOME > Surface Finishing Tutorial > #221 Plating Thickness Test by Microscopic Exam of Cross Section

Surface Finishing Tutorial

#221 Plating Thickness Test by Microscopic Exam of Cross Section

Category : Electroplating

December11, 2015

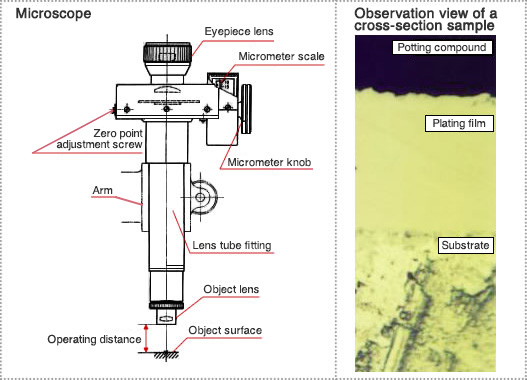

This is a method using a microscope to measure the plating thickness by enlarging the vertical section of a plating layer. The sample used for observing the vertical section is referred to as a cross-section sample, which can be prepared in the steps described below.

(1) Preparation of a cross-section sample

| 1. | Cut out a sample of approximately 10 mm x 10 mm square from the significant surface of the plated product. Gently remove the burr. | |

| 2. | After cutting out the sample, clean it with solution such as organic solvents to remove oil content and dirt. | |

| 3. | Place the sample in a metallic or plastic mold so that the significant surface faces in the vertical direction. Then, harden it with resin (by room temperature setting or thermosetting). In general, the finished size will be approximately 25⌀ or 30⌀ x 23 mm.This is called potting compound. | |

| 4. | Use a dedicated grinding machine to polish the sample surface by splashing a small amount of water. Start with the coarse abrasive grains. Use #1000 or #1200 for final polishing. In addition, use abrasive agent such as alumina to polish more (buffing) for mirror finish. | |

| 5. | If necessary, use etching solution and corrode the plating layer or substrate to make the interlayer areas more optically visible. The methods include corroding the plating layer or the substrate. |

(2) Measurement

| 1. | To keep the polishing surface of the sample perpendicular to the optical axis of the microscope, use a dedicated press machine together with rubber clay for "centering" work. | |

| 2. | Observe the sample by a metallographic microscope or a micro Vickers hardness meter and measure the plating thickness. (Note) It is necessary to implement a measure to prevent sagging of soft plating during polishing work. |

- Environmental conservation

- Hot Dipping

- Anodic Oxidation Process

- Anodic oxidation treatment

- Anodizing

- Corrosion - Corrosion Protection

- Electroless Plating

- Electroplating

- Heat treating

- Hydrogen embrittlement

- Metal cleaning

- Metal etching

- Painting

- Special paints

- Surface Treatment

- Surface-treated steel sheets

- Thermal Spraying