HOME > Surface Finishing Tutorial > #311 Grades of Nickel and Chrome Plating on Copper and Copper Alloy Substrates

Surface Finishing Tutorial

#311 Grades of Nickel and Chrome Plating on Copper and Copper Alloy Substrates

Category : Electroplating

September29, 2017

This standard defines the types of plating applied on copper and copper alloy substrates for decorative and anti-corrosion purposes, as well as the plating thickness of the significant surfaces and the corrosion-resistance properties.(The corrosion resistance properties are described in another section.)

[Table] Nickel and chrome plating on copper and copper alloy substrates

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| * | The plating thickness of duplex nickel plating will be determined and agreed between the parties concerned. |

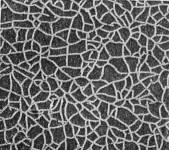

Cr mc: Microgram of microcracked chromium plating surface

|

This is a type of chrome plating containing evenly distributed micro-cracks, which are designed to distribute corrosion current and improve the anti-corrosion properties. This type of deposit can be formed by applying chromium plating over a special type of nickel plating on a nickel-plated substrate, or the same cracks can be generated over a thick layer of chromium plating. |

|

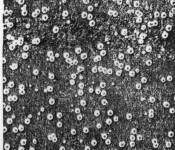

Cr mp: Microgram of microporous chromium plating surface

|

This is a type of chrome plating containing evenly distributed tiny pores in its surface. The pores are designed to distribute corrosion current and improve the anti-corrosion properties. This type of deposit can be formed by applying chromium plating over nickel coating containing non-conductive fine particles, or by directly applying chromium coating containing non-conductive fine particles. |

|

- Environmental conservation

- Hot Dipping

- Anodic Oxidation Process

- Anodic oxidation treatment

- Anodizing

- Corrosion - Corrosion Protection

- Electroless Plating

- Electroplating

- Heat treating

- Hydrogen embrittlement

- Metal cleaning

- Metal etching

- Painting

- Special paints

- Surface Treatment

- Surface-treated steel sheets

- Thermal Spraying