HOME > Low Cost Automation Tutorial > #002 Precision Shafts

Low Cost Automation Tutorial

#002 Precision Shafts

Category : Linear Motion Components

July14, 2009

Due to their simple structure allowing high dimensional accuracy in machining, shafts are used for high precision linear guides. Misumi shafts feature:

| * | Fit tolerance g6 (for requirement of precision motion with fine linear accuracy) or f8 (for use with grease or oil-lubricated bearings). | |

| * | High surface hardness with employment of induction hardening and hard chromium plating. | |

| * | Excellent circular tolerance and straightness plus concentricity and perpedicularity of finish ends. | |

| * | A wide choice of end finishes. |

Examples of linear motion applications using shaft(s)

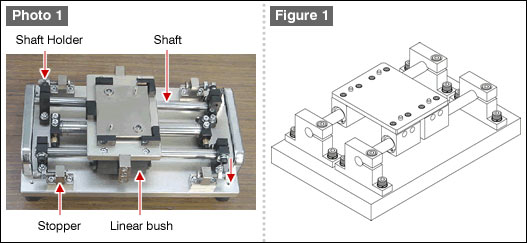

a) Typical linear mechanism using two parallel shafts (see Figure 1 and Photo 1)

| 1. | Using two shafts eliminates displacement, achieving high-precision linear motion capability and high load capacity. (See Photo 1) | |

| 2. | Two types of bushings are available: linear bushings and oil-free bushings. Typically, linear bushings are used. | |

| 3. | Oil-free bushings have high load capacity (compared to linear bushings) and are recommended for mechanisms subject to shock. Oil-free bushings, however, have larger friction resistance compared to linear bushings (which contain linear ball bearings), and should not be used for mechanisms subject to long continuous operations. |

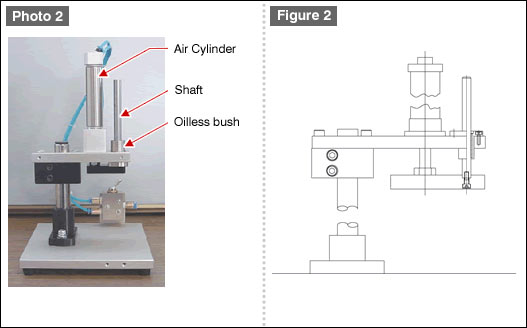

b)Linear mechanism using a single shaft (see Figure 2 and Photo 2)

| 1. | With a linear mechanism using a single shaft, the shaft can serve as a motion guide involving linear and rotaty motions or as a linear guide by restraining rotation. Figure 2 shows the latter case. | |

| 2. | The linear mechanism prevents rotation because the cylinder piston is acting as a second shaft. Therefore this configuration is not suitable for applications that require high load capacity. Photo 2 shows an example of using a linear shaft and air cylinder. | |

| 3. | For a single-shaft mechanism, either long linear bushings (double-type or long-type) or oil-free bushings (for intermittent motions) should be selected to obtain linear stability and high load capability. |

- Positioning technology

- Designing and processing

- Sensor Technology

- Automation elements technology

- Clean room technology

- Design hints

- Design tips

- Designing and Machining

- Drive mechanism design

- Hints on designing

- Linear Motion Components

- Locating Technology

- Manufacturing technology

- Motion mechanism design

- Pneumatic Drives

- Production Technology

- Technology Outlook

- General description

- Low-cost automation and materials

- Transfer LCA

- #333 Know-how on automation: Pressurized heating technology - 5: Multilayer pressurized heating process technique

- #332 Know-how on automation: Pressurized heating technology - 4: Points to remember when designing mechanism of pneumatic pressurization method

- #331 Know-how on automation: Pressurized heating technology - 3: Pneumatic pressurization method and pressure profile

- #330 Know-how on automation: Pressurized heating technology - 2: Pressurization method and pressure profile

- #329 Know-how on automation: Pressurized heating technology