HOME > Low Cost Automation Tutorial > #212 Design Image Training - 28: Design Steps for Large-Scale Automation Device

Low Cost Automation Tutorial

#212 Design Image Training - 28: Design Steps for Large-Scale Automation Device

Category : Drive mechanism design

September11, 2015

If you design a large-scale automation device comprising of a considerable number of mechanical components and drive units in your own way, you will encounter various problems later on.Although the CAD design tools save you the trouble of preparing drawings manually, the overall design will not turn out as intended if you start the design process without thorough preparation.This section introduces the key points of designing a large-scale automation device.

Overall design and subunit design of a large-scale automation device

- Regardless of the machine size, the following functional partitioning is possible:

- The overall design of a large-scale automation device should incorporate the followings without including unnecessarily complex designs: (1) Design layout information, (2) Layout design to maintain drive mechanism consistency among all the subunits, (3) Instruction on adopting unified specifications to the control systems.

- The important factor in the overall design is to set up rules for a large-scale automation device.The device specifications are the important factor in case of subcontracting manufacturing.

- The example includes adopting the same working height or limiting the maximum height for all the subunits, and adopting the same signal system used to control each unit, etc.

- Without setting up the overall design rules, overall control may fail owing to inconsistency in the PLC control specifications among the units.(This problem occurs when adopting PLCs from different manufacturers in the units manufactured by several subcontractors, for example.)

- Detailed design should be divided into subunits - The assembly drawing should be designed respectively according to its division.

- In the phase of dividing the design into subunits and preparing the parts assembly drawings, incorporate specific details on the following concepts into the design: (1) Standardization, (2) Shortened delivery time, (3) Lower cost, (4) Ease of maintenance, etc.

- To avoid making one drawing overly complex in the subunit design of a large-scale machine, it is important to prepare detailed design drawings by limiting the number of machined parts to no more than 50 in each block.

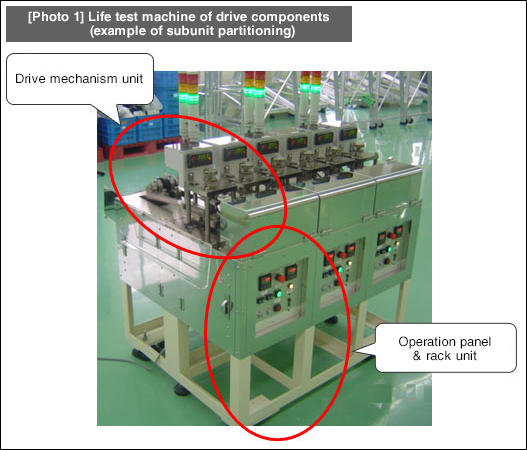

- In the case of a life test machine of drive components shown in the photo, detailed design drawings are prepared by dividing the machine components into the drive mechanism unit and the operation panel & rack unit.

- Positioning technology

- Designing and processing

- Sensor Technology

- Automation elements technology

- Clean room technology

- Design hints

- Design tips

- Designing and Machining

- Drive mechanism design

- Hints on designing

- Linear Motion Components

- Locating Technology

- Manufacturing technology

- Motion mechanism design

- Pneumatic Drives

- Production Technology

- Technology Outlook

- General description

- Low-cost automation and materials

- Transfer LCA

- #333 Know-how on automation: Pressurized heating technology - 5: Multilayer pressurized heating process technique

- #332 Know-how on automation: Pressurized heating technology - 4: Points to remember when designing mechanism of pneumatic pressurization method

- #331 Know-how on automation: Pressurized heating technology - 3: Pneumatic pressurization method and pressure profile

- #330 Know-how on automation: Pressurized heating technology - 2: Pressurization method and pressure profile

- #329 Know-how on automation: Pressurized heating technology