HOME > Low Cost Automation Tutorial > #011 Bearing Mounting/Retaining Method - 1

Low Cost Automation Tutorial

#011 Bearing Mounting/Retaining Method - 1

Category : Automation elements technology

September11, 2009

| A bearing (rolling ball bearing type) needs to be retained in three directions, radial, axial, and circumferential in relation to it's housing and a shaft. The radial and circumferential direction retention is mainly based on a concern on fit tolerance selection (see Tutorial #103). The remaining "axial direction" retention cannot be solved by press fitting of the bearing. The axial retention methods will be explained here with examples. |  |

For instance, high speed bearings such as end bearings for ballscrews will require some measures against heat expansion, but here we'll discuss bearing mounting methods for low to medium speed bearings.

(1) MISUMI's bearing mounting/retaining components

Following standard components are available.

Example 1 (See [Fig.1])

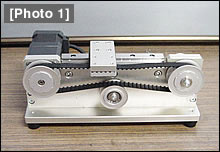

Mounting method for belt tension adjusting idler pulley bearing

| ・ | The idler pulley is mounted with a cantilever pin. This example uses a nut tightened cantilever type. | |

| ・ | Bearing retaining collar" is used to fix the idler pulley bearing. | |

| ・ | A washer is placed between the bearing and the collar to provide an ample access to the collar's tightening screw. | |

| ・ | The washer O.D. should match the O.D. of the bearing's inner ring. |

Example 2 (See [Fig.2])

V-groove idler pulley mounting with a bearing end cap.

|

|

- Positioning technology

- Designing and processing

- Sensor Technology

- Automation elements technology

- Clean room technology

- Design hints

- Design tips

- Designing and Machining

- Drive mechanism design

- Hints on designing

- Linear Motion Components

- Locating Technology

- Manufacturing technology

- Motion mechanism design

- Pneumatic Drives

- Production Technology

- Technology Outlook

- General description

- Low-cost automation and materials

- Transfer LCA

- #333 Know-how on automation: Pressurized heating technology - 5: Multilayer pressurized heating process technique

- #332 Know-how on automation: Pressurized heating technology - 4: Points to remember when designing mechanism of pneumatic pressurization method

- #331 Know-how on automation: Pressurized heating technology - 3: Pneumatic pressurization method and pressure profile

- #330 Know-how on automation: Pressurized heating technology - 2: Pressurization method and pressure profile

- #329 Know-how on automation: Pressurized heating technology