The following are the required properties of the functional platings.

|

(1) Hardnes

Hardness of plating layers are represented in Micro Vickers Hv and Knoop Hk hardness values. The industrial chrome plating can attain Hv800~1000, and heat treated electroless nickel plating can attain Hv1000. Also, composite plating where minute particles of alumina and silicon carbide are dispersed in nickel plating can attain Hv600. These can achieve Hv1300~1400 by heat treating. Nickel-tungsten alloy plating is also spotlighted as a high hardness plating.

(2) Lubricity

The term Lubricity includes low friction coefficient, lubricant retention characteristics, and conformability. For bearings, lead-tin alloy, lead-indium alloy, lead-tin-antimony alloy, and silver give the conformability. When wear resistance is needed, lubrication impregnated composite plating or porous chrome plating are used. For the lubricity and wear resistance purposes, composite platings where minute particles of graphite fluoride or molybdenum disulfide are dispersed.

(3) Dimensional accuracy

There are issues in uneven plating current with electroplating, and is difficult to evenly deposit the coatings everywhere on the objects. But with electroless platings that do not use electricity, it is possible to obtain even coating layers easily. There are nickel-phosphate plating and nickel-boron alloy plating.

(4) Buildup characteristics

This is a type of plating used for dimensional corrections and repairs, as well as good wear resistance, corrosion resistance, hardness, machinability are required at the same time. The plating types able to achieve high harness and thick plating layers are used.

(5) Demolding characteristics

| This is required for mold applications, and the industrial chrome plating is used. Instead of the chrome plating, graphite fluoride dispersed nickel plating is also used, contributing in prolonging mold lives. |  |

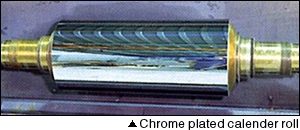

(6) Low friction coefficient

This is also termed "sliding properties", and is required for papermaking roller and guide applications. Teflon impregnated industrial chrome plating and molybdenum disulfide codeposited nickel composite plating are attracting the attention.