Industrial plating that imparts functions such as corrosion resistance, wear resistance, and electrical characteristics is introduced here.

Applications of industrial nickel plating are classified as shown in the [Table].

[Table] Industrial uses of nickel plating

| Types of plating baths | Usage |

| Electroplating | Watts bath | In general, it is used as a base-coat plating to improve corrosion resistance of decorative plating, but it is also used for providing brazeability, weldability, and bondability to the stems and caps of semi-conductor components. Adhesion is crucial. 0.1 to 30 um |

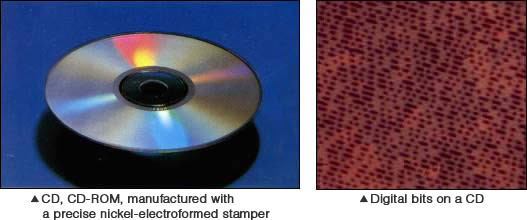

| Sulfamate bath | It is used for cladding of recycled parts as a thick plating.As an electroforming bath, it is an essential plating for the production of CD stampers, resin molding dies, and metal bellows. |

Electroless plating

Ni-P, Ni-B | Nickel-phosphorus and nickel-boron alloys, etc. can be obtained.Electroless plating can achieve a film with uniform thickness on complicated shapes and therefore is used for parts that require accuracy.It has superior hardness, corrosion resistance, and electrical characteristics. |

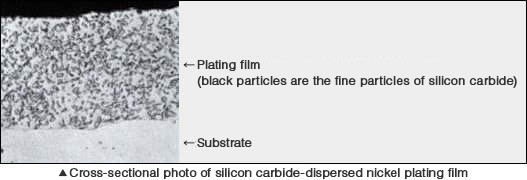

| Special plating | Dispersal plating | It is also known as composite plating.Dispersal plating can improve wear resistance and lubricity and add color by dispersing fine particles, such as ceramic particles, in the nickel film. |

| Ni-Cddiffusion plating | Following the application of cadmium plating on top of nickel plating, heat treatment at 300°C is carried out to diffuse cadmium into nickel. This plating technique enhances heat resistance and seawater corrosion resistance. |

|

Nickel plating for precision parts (Electroplating)

Semi-bright and bright plating deposited by the Watts bath are used as base-coat plating for various types of industrial plating.

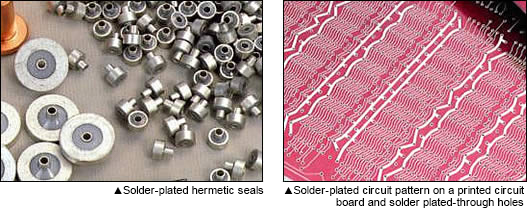

Base-coat plating of gold, tin, and rhodium for connectors, switches, terminals and lead frames is an example of nickel plating usage that enhances corrosion resistance and adhesion and that contributes to preventing diffusion of such metals into the substrate.

Furthermore, application of about 0.1 to 0.3 um nickel strike plating as a base coat improves the adhesion, mechanical strength, and shock absorption of materials, such as stainless steel and kovar, for which normal plating techniques do not provide satisfactory adhesion.